We Can Show You How

Thermal Management Solutions

Increasing heat concerns in cell phones and other hand held devices or higher power electronics are pushing the limits of heat sink technology. Our clad metal materials offer better thermal performance without sacrificing weldability or aesthetics. The wide range of brazing temperatures of EMS titanium brazing foils can also provide flexibility for brazing and heat treating of titanium and titanium alloys – We can show you how.

Titanium Brazing Foils

The EMS family of titanium based brazing foils has been developed to address the technical challenges of brazing titanium and titanium alloys. Brazing applications include jet engine exhaust, aerospace and industrial heat exchangers. Brazing filler in foil form provides more consistent joint quality than braze powder which is prone to particle size variation. Additionally, no binder is required (binder variability can cause uneven powder deposition).

For more information CLICK HERE

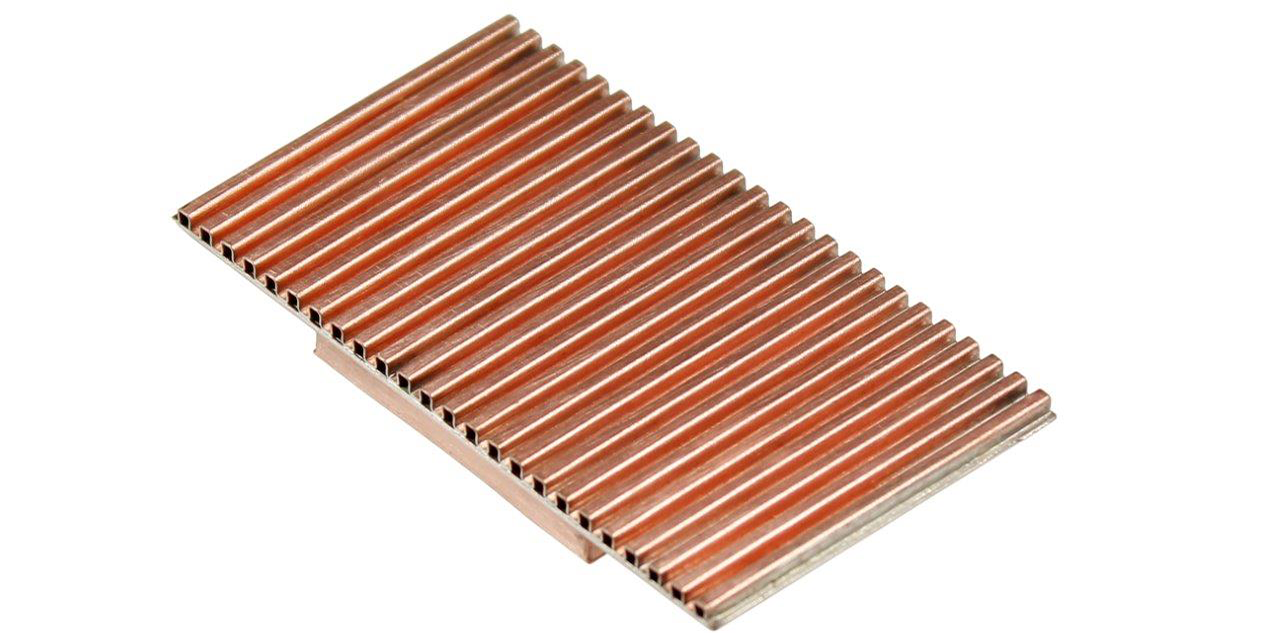

Handheld Device Heat Sink

Increasing heat concerns in cell phones and other hand held devices or higher power electronics are pushing the limits of heat sink technology. Copper or aluminum clad stainless offers better thermal performance while not sacrificing weldability or aesthetics.

For more information CLICK HERE

IGBT Modules

Increased heat and thermal dissipation requirements demand new cooling solutions designed around current automotive systems. Copper Clad Aluminum up to 7mm in thickness can solve many of these needs.

For more information CLICK HERE

Printed Circuit Boards

Cladding copper to an Invar (36 Ni, balance Fe) core produces a constraining metal layer well known to the electronics packaging, heat sink and printed wiring board industries. This material is mil certified and the preferred constraining layer of choice for demanding electronics applications.

For more information CLICK HERE

LED Heat Sink

Improving LED lighting reliability is possible by removing excess heat using copper clad heat sinks.

For more information CLICK HERE