Step into the Future

Battery Systems

We understand that energy efficiency and safety are key factors in today’s market. Our high quality Clad Materials are the preferred choice because of their unique multi-layer properties, especially as performance demands increase for higher energy, smaller cells for hearing aids and other electronic devices. We can help you choose the best clad metals for many of your applications, such as Automotive Hybrid Electronics, Power Conversion and Energy Storage.

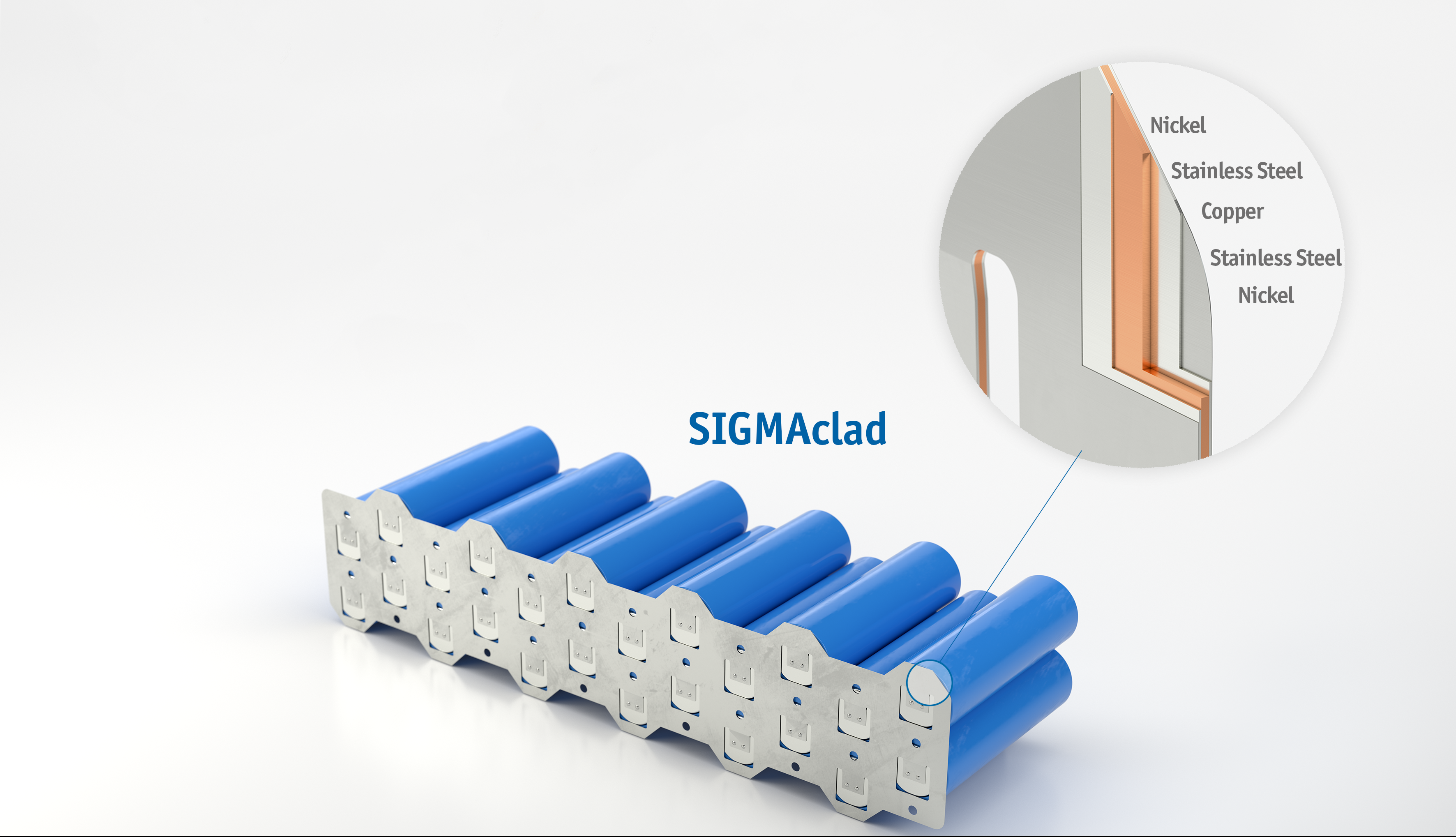

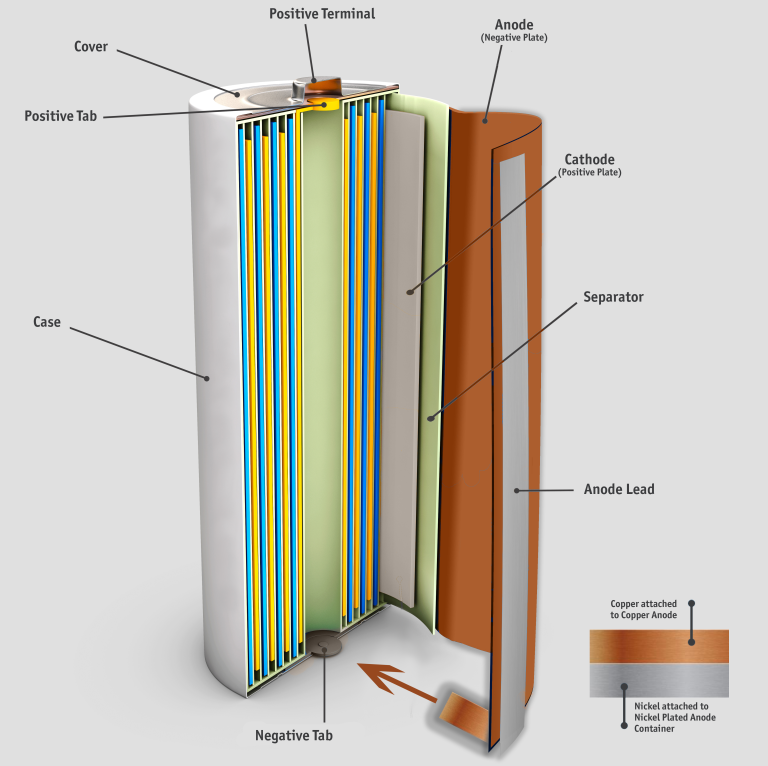

Li-Ion Cell Connectors

SIGMAclad is a 5-Layer clad material composed of Ni/SS/Cu/SS/Ni created specifically for busbars in Li-Ion Battery Packs. It is designed with superior properties compared to other materials used in these applications like Nickel or Nickel Plated Steel . The Copper layer provides enhanced electrical and thermal conductivity for heat dissipation. The Stainless Steel layers facilitate resistance welding and increases weld strength. The exterior layers of Nickel allow for easy soldering and provide enhanced corrosion resistance. All of these features are provided at a cost that can be lower than pure Nickel and competitive with Nickel Plated Steel.

For more information CLICK HERE

Anode Leads

Ni/Cu tabs improve joining of the copper anode to the negative terminal of the can. Ni/Cu/Ni also provides thermal benefits in higher power applications. Copper Nickel provides high conductivity lead material to lower heat generation and improve safety.

For more information CLICK HERE

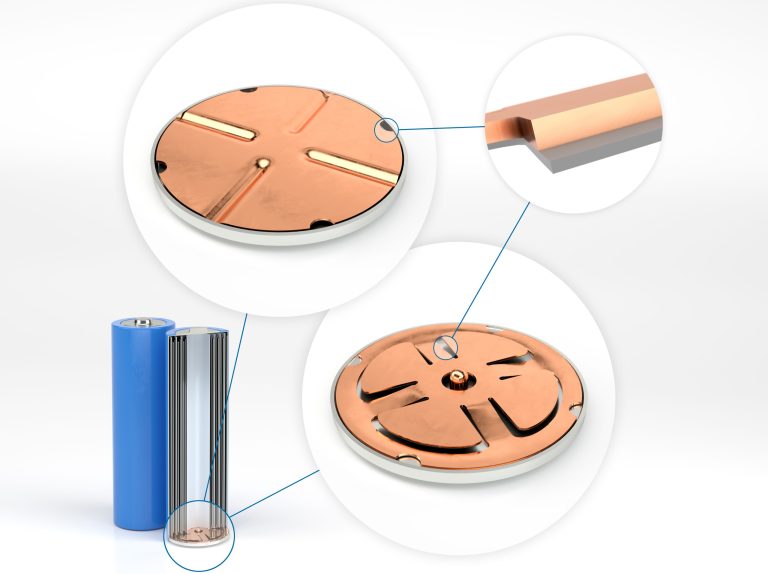

Steel / Copper Stamped Parts

Steel / Copper clad strip and stamped parts for tabless lithium-ion cells. Copper side for connection to the jelly roll. Steel side for connecting to the terminal. Three times the conductivity compared to Nickel disks. Easier to assemble than Copper disks. Strip or stamped parts to your design. Competitive price compared to Nickel disks and Copper disks.

For more information CLICK HERE

Copper Aluminum Busbars

EMS CoreLok is an edge bonded Copper-Aluminum product for joining Li-Ion cell terminals made from Copper and Aluminum. CoreLok can also be used to replace cathode or anode tabs to simplify bussing.

For more information CLICK HERE

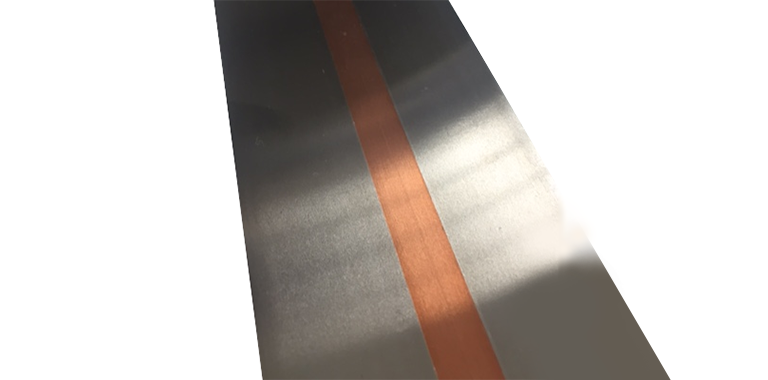

Inlay Clads

Ni/Cu tabs improve joining of the copper anode to the negative terminal of the can. Ni/Cu/Ni also provides thermal benefits in higher power applications. Copper Nickel provides high conductivity lead material to lower heat generation and improve safety.

For more information CLICK HERE

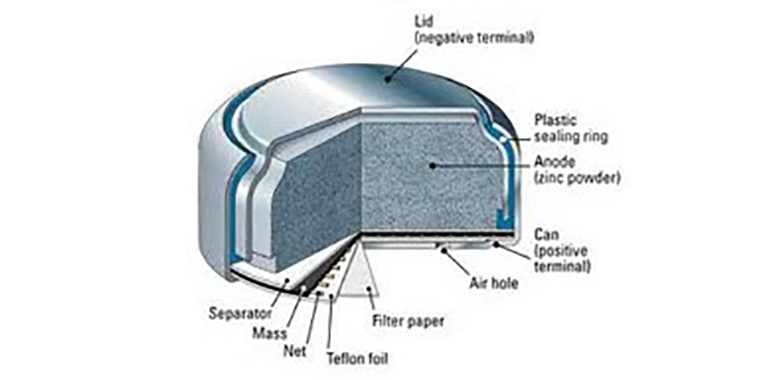

Zinc Air Button Cell Batteries

An important application for clad materials is in the button cell battery industry for use as both the anode lid and cathode cup. In each case, clad is the preferred choice because of its unique multi-layer properties especially as performance demands increase for higher energy, smaller cells for hearing aids and other electronic devices.

Tri-clad Cu/S304/Ni functions as the anode current collector with its corrosion resistant nickel exterior, strong stainless core and pure copper interior for cell chemistry compatibility with mercury free applications.

For more information CLICK HERE

Silver Oxide Button Cell Batteries

An important application for clad materials is in the button cell battery industry for use as both the anode lid and cathode cup. In each case, clad is the preferred choice because of its unique multi-layer properties especially as performance demands increase for higher energy, smaller cells for hearing aids and other electronic devices.

For the cell cup or cathode, Ni/S430/Ni excels over plated options because of the durability of the clad nickel layer compared to more porous plated solutions. This is especially important to prevent corrosion in hearing aide applications.

For more information CLICK HERE