Ready to get started?

EMS is here for all your toll-processing needs! Email us right here, and an EMS expert will be quick to reach out to tailor services that empower you to locate bottlenecks in your product development and eliminate them.

Contact us right here: solutions@emsclad.com

Get precision processing without overhead with EMS’s toll-processing services.

EMS has over 100 years of experience working with every metal on the planet, creating custom multilayer clad metal solutions for companies worldwide.

EMS has the equipment, expertise, and experience to help you find the perfect solution tailored to your design, industry, and use case.

And now, you can experience industry-leading processing capabilities without worrying about overhead or buying expensive machinery with EMS’s toll-processing services.

EMS Toll-Processing Services

STRIP CLEANING

Various methods and machinery to perfectly remove oils and debris, leaving material prepared for the rest of the processing

- Pickling, aqueous cleaning, alkaline degreasing, and brushing for widths up to 26″ (660 mm)

- Dry grinding available for widths up to 26″ (660mm)

CLADDING

Multiple layers of dissimilar metals are bonded together through rolling or inlay techniques, creating a single strip that combines the strengths of each material

- Cold Rolled Cladding – Up to 4 layers (additional layers possible)

- Widths up to 26″ (660mm); Thicknesses 0.010” – 0.300” (0.25 – 7.6mm)

- Warm Bonding – Widths up to 26″ (660mm)

- Inlay Bonding – skive, crush multiple strips

- Edge Bonding – available upon request

BATCH ANNEALING

Coils are heat-treated in controlled furnace environments to relieve internal stress, improve ductility, and refine grain structure for enhanced formability

- Heat treatment for a range of metals and alloys including aluminum, carbon steel, copper, nickel, stainless ferritic and austenitic steel, and alloys

- Furnace capacity and coil stacking in a protective atmosphere for flexible heat treatment

STRAND AND BRIGHT ANNEALING

Strip is continuously heat-treated in a controlled, oxygen-free atmosphere to soften the material, relieve stress, and maintain a bright, oxide-free surface finish

- Supports widths up to 26″ (660 mm)

- Strand Annealing: Continuous annealing of material

- Bright Annealing: Oxidation prevention strand or batch annealing

SLITTING

Wider coils are cut into narrower strips with tight width tolerances and clean edges, ready for stamping, forming, or further processing

- Widths from 1/8″ (3 mm) up to 26″ (660 mm)

- Gauge range from .001″ (0.036 mm) to .25″ (6.35 mm) and widths up to 26″ (660mm)

ROLLING

Metal strip is passed through high-precision mills to reduce thickness, improve surface finish, and achieve tight gauge tolerances for demanding applications

- Sendzimir 20-high rolling mills for gauges down to .001″ (0.025 mm) and widths up to 26″ (660 mm)

- 4-high rolling mills for gauges up to .25″ (6.35 mm)

LEVELING/SBL

Precision shape correction eliminates coil set, camber, and edge wave, producing flat, stable strip ready for stamping, forming, or automated assembly

- Leveling for coil widths up to 26” (660 mm)

- Auto Shape Control

- Gauge range from .002” (0.0508 mm) to .030” (0.762 mm)

PARTS FABRICATION

Processed strips undergo stamping, forming, welding, and assembly using in-house tooling, transforming them into finished components

- Stamping and forming with 30 to 200 ton presses

- Coil winding, welding, and joining

- Precision assembly for complex builds

- Surface finishing including tumbling, polishing, and electroplating

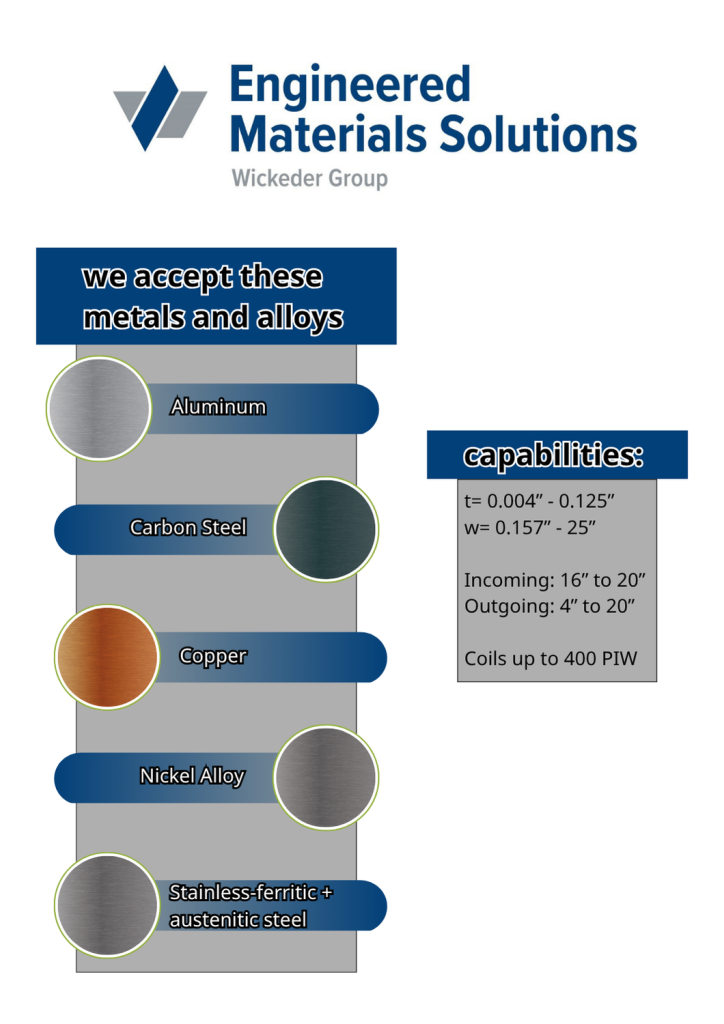

Materials and Sizes We Accept

Why Choose EMS?

For over a century, EMS has helped shape the future of metal manufacturing. From pioneering cold-roll bonding technology to becoming the first supplier to deliver material to the United States Mint, we’ve earned our reputation through consistent innovation, tight-tolerance precision, and a deep commitment to solving the challenges others won’t touch.

When customers hit a wall in production, EMS is often the partner they call next.

Here’s why some of the world’s top manufacturers rely on EMS:

Experience – Decades of proven leadership in metal manufacturing, with deep specialization in advanced clad metal processing for demanding applications.

Capacity – Over 500,000 square feet of production and storage space, equipped to handle everything from full-scale production to prototyping.

Protection – Your materials, designs, and intellectual property are safeguarded by strict confidentiality protocols and handled securely in-house.

Support – Clear, responsive communication and hands-on guidance from project start to delivery—no automated runarounds, no dropped threads.

Flexibility – From one-off development runs to full production loads, EMS offers fast turnaround and batch-size agility tailored to your needs.

Expertise – Work directly with engineers and process specialists who understand the materials, the machinery, and the real-world demands of your industry.

Looking for a trusted toll-processing partner?

Let’s talk. EMS can help you expand capacity, test new materials, or meet tight deadlines without the need for new equipment.

Contact us right here: solutions@emsclad.com

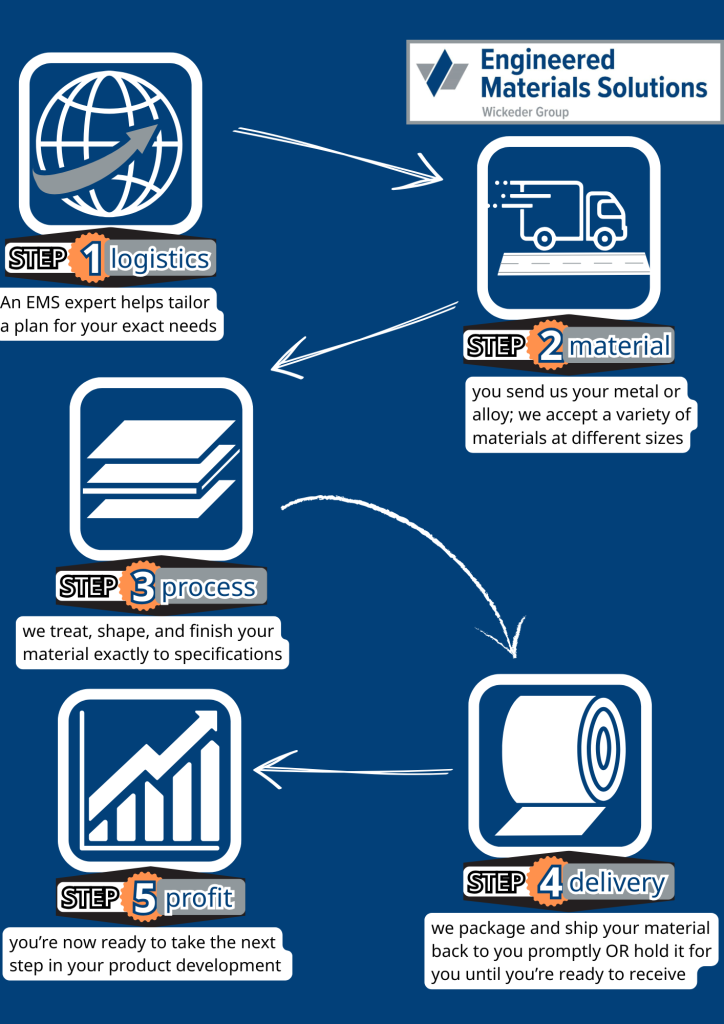

How it Works

From there, we’ll expertly process your materials through our pre-approved toll-processing services at our impressive 500,000 square-foot manufacturing facility.

Our services include cleaning, shaping, finishing, packaging, and shipping, all executed with unparalleled precision by EMS professionals.

By partnering with us, you can advance your product development, create new prototypes, or scale at a moment’s notice without incurring costly investments in machinery, labor, or infrastructure.

Ready to take the next step?

Just email us here solutions@emsclad.com and say you’re interested in toll-processing! A team member at EMS will be quick to respond and start your journey to finding the perfect toll-processing services you need!